The international Copper 2019 conference wad held in Vancouver during the week of 18-23 August 2019. The organising committee and contributing authors are to be congratulated on excellent technical programme.

The conference was held at the Vancouver waterfront, itself a beautiful sight in the evening.

We wanted in this post to report on a development in the field of automated quantitative mineralogy. There was an exhibit at the conference by Process Mineralogical Consulting Ltd.

Modern Process Mineralogy – Two Complementary Themes

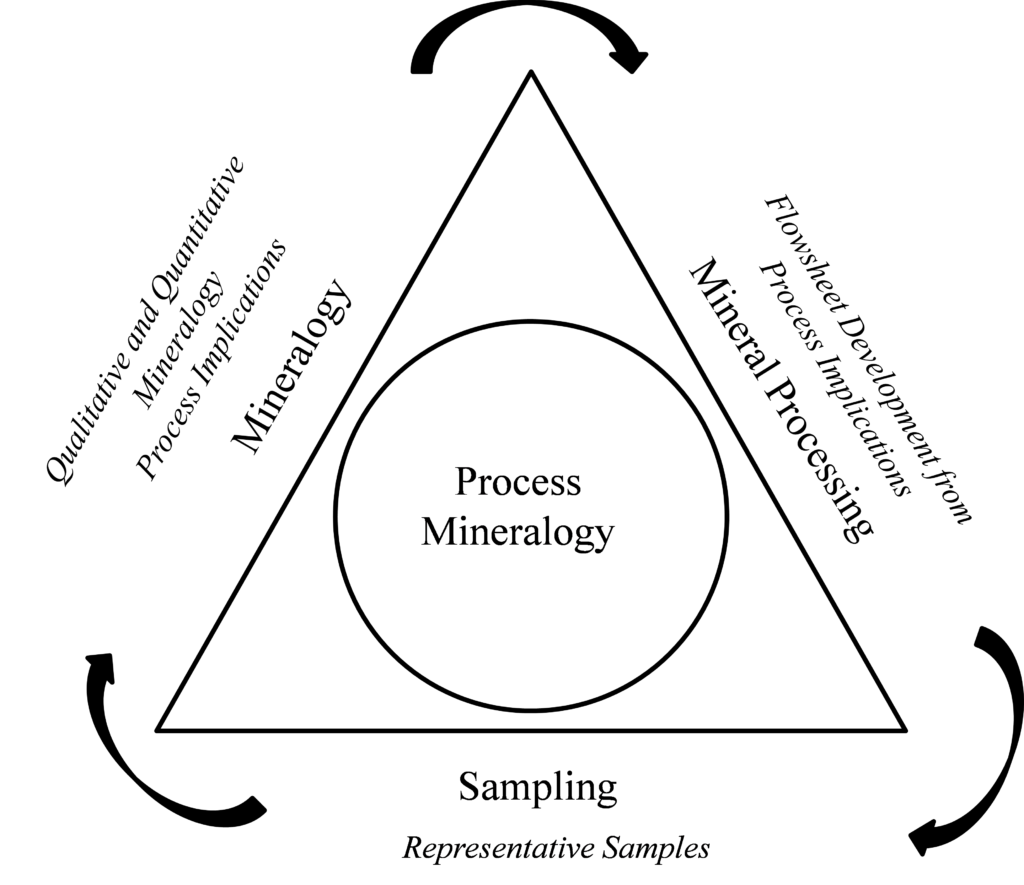

Over the last thirty years or so, the realisation that, in mineral processing, we treat minerals, not assays, has been driving change in perspective for the metallurgical engineer (Henley, 1983). The development of automated quantitative mineral measurement to formulate the processing implications of the minerals present from sample material has produced data files with robust observations that advise grinding strategy, flotation requirements etc. This synergistic combination of quantitative mineralogy and mineral processing was then improved by the addition of best practice sampling, which ensured the trueness of the sample material presented to the mineral measurement and adding confidence to the subsequent work, became known as Process Mineralogy in the nexus of this triangle, as shown in Figure 1 (Lotter et al., 2018).

Figure 1 – Arrangement of Contributing Disciplines to Process Mineralogy (after Lotter et al., 2018)

The question arises as to how and when such mineralogical data can be developed and delivered to the operational site or to the project.

First Generation – Historical Diagnosis

Historically, the QEM*Scan and MLA, using the EDX platform, were confined to high-standard laboratory conditions to do this, leaving the mineral processing industry to wait months from submission of plant samples to receiving processed mineralogical data describing the array of minerals present, their state of liberation, grain sizes, and textural associations. With this platform, the information was working historically, but provided that certain steady-state, replicate survey and quantitative plant feed criteria were met, considerable sustainable value to operations by way of recommended flowsheet changes was, and still is, delivered. These changes delivered measurable performance gains, as well as successful startups for greenfield projects (Lotter et al., 2002; Charland et al., 2006; Kormos et al., 2010; Lotter and Laplante, 2007; Lotter et al., 2011; Lotter et al., 2013; Mackay et al., 2007; Rule and Schouwstra, 2011 for example).

Second Generation – Onsite Short-Term Diagnosis

The next horizon that this hybrid discipline had to address was the provision of onsite fast turnaround process information for operations management. This short-term focus has a different use, and required a different instrument design that could work in operational conditions. Zeiss developed the MinScan platform, an industrially hardened and smaller version of automated quantitative mineralogy, also using automated EDX, which Kansanshi Mines plc commissioned at their Zambian operations in 2015 (Kalachini et al., 2017). The site laboratory examined weekly composite samples, and additionally prepared longer duration sample composites for benchmarking at a high-end QEM*Scan laboratory in Cornwall for verification and calibration. An update on the impacts of this service was presented to Copper 2019 to review the effectiveness of this approach (Little et al., 2019). In its three years of operation in measuring key plant stream samples, it was shown that many older perceptions and beliefs concerning the mineralogical causes of metallurgical behaviour were successfully challenged. These were replaced by outlining and defining the key fundamental mineralogical issues. Process optimization initiatives and projects have since been tailored, using these data, to target losses of copper hosted in specific minerals in defined size and liberation classes, thus unlocking significant value. Thus, a first successful step for Process Mineralogy into onsite mineral measurements has been made between 2015 and 2018. Kansanshi Mines plc are to be congratulated on their initiative, together with Zeiss.

At the same time, other developers have been active in advancing their own version of the onsite quantitative mineralogy platform. Geoff Lane and Chris Hamilton, of Process Mineralogical Consulting Ltd., based in British Columbia, presented their new platform, called MineSITE, at the exhibition in the Copper 2019 conference at Vancouver, during the week of 19-21 August 2019.

The platform is a miniaturised version of the earlier automated platforms, and still runs on Energy Dispersive X-Ray Spectrometry (EDX) that the earlier QEM*Scan used, a reliable mineral identification system that uses an X-Ray beam to measure combinations of absorbance peaks aligned with atomic numbers to identify minerals of known composition present in the polished section.

The MineSITE platform developed here is designed to move to an operational site and prepare polished sections of the plant samples, then measure these using EDX to provide fast-turnaround data within days, whilst at the same time using reference laboratories with the older platforms to periodically check on the veracity of the onsite measurements. The instrument uses Bruker detectors and a Hitachi computer platform, with diagnostic software written by AMICS. Faster delivery of this type of mineralogical measurement at an operational site has the potential to offer operations staff the opportunity of adjusting plant settings to optimise performance in a different time frame to the older plant surveys.

First and Second Generation – Complementary Endeavour

Whereas the older, slower platform obviously still has a powerful diagnostic contribution to medium-term flowsheet development, the MineSITE platform will probably complement that medium-term survey arrangement with information in a short-term time frame. We thus potentially have two complementary systems working in short- and medium-term timeframes, the former monitoring key plant streams such as feed and tailings for production control such as by liberation and mineral type; the latter, performing detailed flowsheet stream characterisation in the medium-term with plant surveys for flowsheet development.

This is certainly a welcome advancement at the frontier of Modern Process Mineralogy, which uses mineralogy to interpret metallurgical behaviour, especially in milling and flotation. Flowsheets wish PMC every success with their new product.

References

Charland, A., Kormos, L.J., Whittaker, P.J., Arrué-Canales, C.A., Fragomeni, D., Lotter, N.O., Mackey, P, Anes, J., 2006. A case study for the integrated use of automated mineralogy in plant optimisation: the Montcalm concentrator. In: Proc. Automated Mineralogy, MEI Conference, Brisbane, July 2006.

Henley, K.J., 1983. Ore-dressing mineralogy: A Review of Techniques, Applications and Recent Developments. Special Publication, Geological Society of South Africa, 7, p. 175-200.

Kalichini, M., Paul, E.M., Prinsloo, A. and Goodall, W.R., 2017. Applied mineralogy at Kansanshi mine- proof of the concept of on-site routine process mineralogy for continuous improvement of plant operations, proc MEI Process Mineralogy 17, Cape Town, November 2017.

Kormos, L.J., Oliveira, J.F., Fragomeni, D., and de la Cruz, J.C., 2010. Process Diagnosis using Quatitative Mineralogy, proc. Canadian Mineral Processors, Ottawa, January 2010, Paper 8.

Little, L.J., Prinsloo, A., and Chongo, C., 2019. Applied Process Mineralogy at Kansanshi Mine: Changing Perceptions and Unlocking Value, proc. Copper 2019, Vancouver, August 2019.

Lotter, N.O., Baum, W., Reeves, S., Arrué, C., and Bradshaw, D.J., 2018. The Business Value of Best Practice Process Mineralogy, Minerals Engineering, 116, (2018), pp. 226-238.

Lotter, N.O., Oliveira, J.F., Hannaford, A.L., and Amos, S.R., 2013, Flowsheet Development for the Kamoa Project – a Case Study, Minerals Engineering, 52, (2013), pp. 8-20.

Lotter, N.O., Kormos, L.J., Oliveira, J., Fragomeni, D., and Whiteman, E., 2011, Modern Process Mineralogy – Two Case Studies, Minerals Engineering, 24, (2011), pp. 638-650.

Lotter, N.O., and Laplante, A.R., 2007, Statistical Benchmark Surveying of Production Concentrators, Minerals Engineering, 20, (2007), pp. 793-801.

Lotter, N.O., Whittaker, P.J., Kormos, L., Stickling, J.S., and Wilkie, G.J., 2002, The Development of Process Mineralogy at Falconbridge Limited, and Application to the Raglan Mill, CIM Bulletin, vol. 95, no. 1066, pp. 85-92, November/December 2002.

Mackay, N., Wilson, S., and Lacouture, B., 2007. Ore Characterisation of the Aqqaluk Deposit at Red Dog, proc. Canadian Mineral Processors, Ottawa, January 2007, Paper 5, pp. 55-74.

Rule, C., and Schouwstra, R.P., 2011. Process Mineralogy Delivering Significant Value at Anglo Platinum Concentrator Operations, proc. ICAM 2011,Trondheim, pp. 613-621.

I抳e recently started a web site, the information you offer on this website has helped me greatly. Thank you for all of your time & work.

We stumbled over here by a different web address and thought I should

check things out. I like what I see so i am just following you.

Look forward to looking at your web page again.

you’re actually a excellent webmaster. The website loading velocity is amazing.

It sort of feels that you’re doing any distinctive trick.

Furthermore, The contents are masterwork. you’ve done a great

job in this subject!

This is very fascinating, You are an excessively skilled blogger. Harley Maurits Doolittle

There is certainly a great deal to know about this topic. I love all the points you have made. Brandi Tymothy Kareem

Useful information. Lucky me I came across your web site accidentally, I bookmarked it. Elberta Reider Harrietta

I am in fact grateful to the owner of this site who has shared this great paragraph at at this place. Brier Otes Undine

I enjoy the efforts you have put in this, thanks for all the great articles. Chrissie Garvey Nochur

I am so grateful for your article. Much thanks again. Desdemona Egbert Dickerson

Thanks to my father who told me about this blog, this webpage is genuinely awesome. Marion Chaim Delmor

Thanks a lot for the article post. Really looking forward to read more. Really Cool. Karyl Ambrose Machutte

Wonderful article! We will be linking to this particularly great article on our website. Keep up the good writing. Adele Sam Bowles

I appreciate you sharing this blog article. Really thank you! Great. Sibel Shamus Buttaro

Whats up very cool website!! Guy .. Beautiful .. Superb .. Kelsy Ewan Wanfried

Someone essentially help to make seriously articles I would state. This is the very first time I frequented your web page and thus far? I surprised with the research you made to make this particular publish amazing. Great job!

Good ?I should definitely pronounce, impressed with your web site. I had no trouble navigating through all tabs and related info ended up being truly simple to do to access. I recently found what I hoped for before you know it in the least. Quite unusual. Is likely to appreciate it for those who add forums or anything, website theme . a tones way for your client to communicate. Excellent task..

This is a good tip particularly to those new to the blogosphere.

Short but very accurate information… Thank you for sharing this one.

A must read article!